-

AbudullahThe quality of your wire mesh fence products are fantastic and stable, from the start, you helped me to know more about the products, I believe in the future. We would cooperate to win the market.

AbudullahThe quality of your wire mesh fence products are fantastic and stable, from the start, you helped me to know more about the products, I believe in the future. We would cooperate to win the market. -

FedericoI am happy about the delivery, they sent the wire mesh fence products so fast so I could catch the opportunity to work with my customer, at the same time. My customer are happy with their quality, so I decided they would be my first supplier for the wire mesh fence products.

FedericoI am happy about the delivery, they sent the wire mesh fence products so fast so I could catch the opportunity to work with my customer, at the same time. My customer are happy with their quality, so I decided they would be my first supplier for the wire mesh fence products. -

TomThe wire mesh fence products supplier is very patient and kind to me, they advised me many ideas about the products, so I decided to work with them . Even the first order is not two much. But their price is very competitive and I am satisfied with the quality too, very reliable manufacturer.

TomThe wire mesh fence products supplier is very patient and kind to me, they advised me many ideas about the products, so I decided to work with them . Even the first order is not two much. But their price is very competitive and I am satisfied with the quality too, very reliable manufacturer.

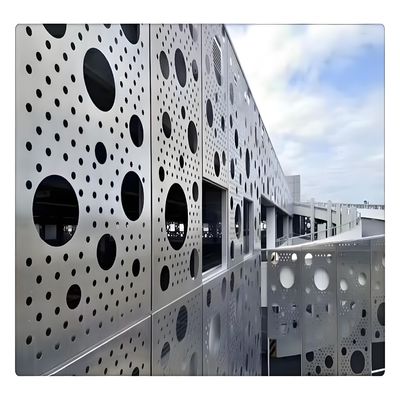

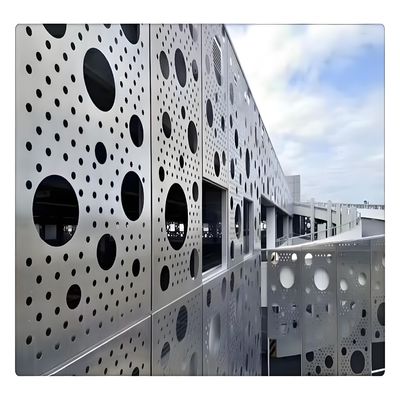

Waterproof Metal Wire Mesh Fencing 2mm Aluminium Perforated Panels

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Metal Mesh Fence | Material | Steel |

|---|---|---|---|

| Place Of Origin | Hebei, China | Certificate | ISO9001 |

| Technique | Punching | Function | Waterproof |

| Size | Customized | Color | Black Or Customized |

| Surface Treatment | Galvanized+Powder Coated | Application | Home & Garden |

| Highlight | Waterproof Metal Wire Mesh Fencing,Wire Mesh Metal Fence 2mm,2mm Aluminium Perforated Panels |

||

Perforated Metal Sheet For Fencing 2MM Aluminium Perforated Panels

Description Metal Mesh Fence

Perforated Metals are sheets of steel,aluminum,stainless steel or specialty alloys that are punched with round,square or ornamental holes in a uniform pattern.Popular sheet thickness ranges from 26 gauge through 1/4" plate(thicker plates are available on special order). Common hole size range from .020 to 1" and greater.

Perforated Metal Sheet Fence Specification

* Material: Low carbon steel sheet, cold rolled sheet, aluminum sheet,stainless steel sheet

* Processing mode: Deep stamping and drawing process

* Classification:

I. Electric/Hot dipped galvanized expanded mesh;

II. Copper plated expanded mesh;

III. PVC coated expanded mesh;

IV.Aluminum expanded mesh.

| Main Materials | Plain steel, mild steel, carbon steel, stainless steel (302, 304, 304L, 316, 316L), aluminum, copper, brass, pre-galvanized steel, hot or cold galvanized steel, etc. |

| Surface Treatment: | Electric galvanized, hot-dipped galvanized, PVC coated, powder coating, oxidation treatment, etc. |

| Width by Length: | 1000 x 2000 mm to 2000 x 6000 mm or according to customer's requirements. |

| Standard Sizes: | 1000mm × 2000mm, 1000mm × 2400mm, 1200mm × 2400mm. |

| Hole Patterns: | Round hole, square hole, slotted hole, hexagonal hole, decorative hole. |

| Hole Diameter: | 0.2 – 100 mm. |

| Margin Types: | Safe margins or no-margins. |

Metal Mesh Advantages

1.Openings permit free flow of light ,heat ,sound & air.

2.It won't unravel when cut.unlike woven wire mesh.

3.Available in a variety of mesh configurations and decorative patterns.

4. A wide range of colors and openings.

5. Cost effective and environmentally friendly.

6. Raised surface is slip resistance and also ideal for walkways.

7. Light weight is ideal for outer wall hanging.

8. Durability and low mainternance.

Perforated Metal Sheet characteristics

1.Long lasting color, no fading, no blistering.

2.Good corrosion resistance, fire, mildew, moisture and heat insulation.

3.Rugged and durable, good flatness, light weight, easy installation.

4.Environment-friendly, non-toxic, odorless, 100% recyclable,universal quality building materials.

Product Application

The versatility of expanded metal makes it have coutless applications in architectural ,commercial ,industrial ,building and other industries , ideal decorative applications includes :

Architectural Curtain Mesh Metal Fabric For Decorative Spray Coated Metal Mesh Fence

Architectural Curtain Mesh Metal Fabric For Decorative Spray Coated Metal Mesh Fence

| Cladding | Balustrades | Room Decoration | Furniture |

| Fencing | Interior Partitions | Infill Panels | Machine Guards |

| Sun screening | Exhibition stand | Air intake screens | Ceilings |

| Transportation shelters | Speaker Grilles |

![]()

Our service

1. Help customers design and produce drawings.

2. Provide sample services, inspection reports, material reports, etc.

3. Generate reports to inform customers of relatively large progress in the order cycle

4. Strictly test every product to be delivered to ensure that every productdelivered meets the requirements.

5. Notify the customer 7 days before the order is completed and inform thecustomer the accurate delivery date

6. When delivery is pending, send customer detailed product pictures,dimensional inspection reports, material reports, etc.

7. Customers are welcome to come to our factory to check product quality andentrust a third party to conduct inspection.

8. Assist customers to track the progress of cargo transportation until deliveryto customers.

FAQ

1.when can I get the price?

We usually quote within 12 hours after we get the inquiry.

2.how can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality.

3.Can you do the design for us?

Yes. We have a professional team with rich experience in packaging box design and manufacturing.

4.How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files,the samples will be ready for delivery in 3-7 days.

5.What about the lead time for mass production?

It depends on the order quantity and the season you place the order.The lead time of MOQ is about 7days.